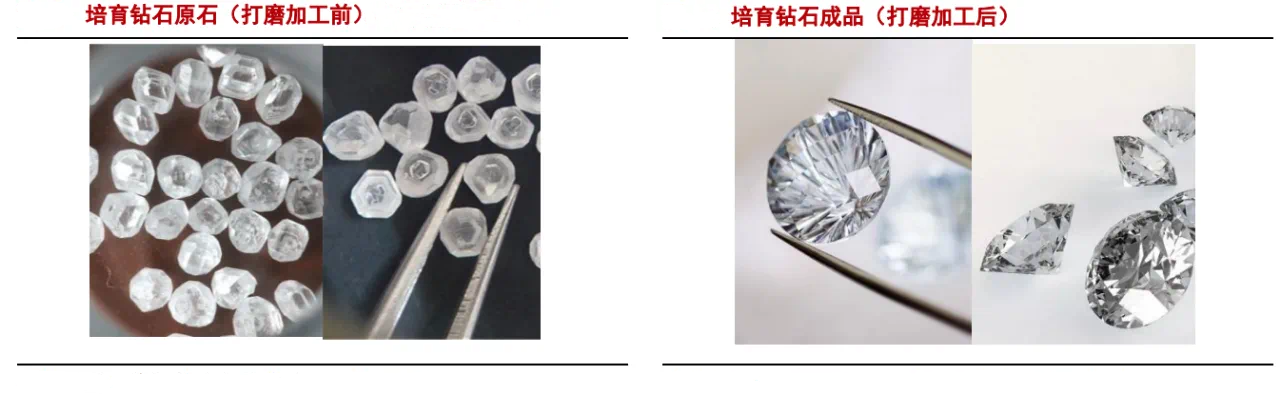

Diamonds have always been one of the precious gems pursued by people, but it is not easy to obtain high-quality diamonds in nature. Therefore, people cultivate diamonds through artificial methods to meet the needs of the market. So, how is diamond achieved?

The cultivation process of diamonds can be traced back decades ago, when scientists began to study the use of high-temperature and high-pressure technology to synthesise diamonds. Nowadays, the method of cultivating diamonds has been greatly improved, so that the quality and size of synthetic diamonds can meet the commercial standard.

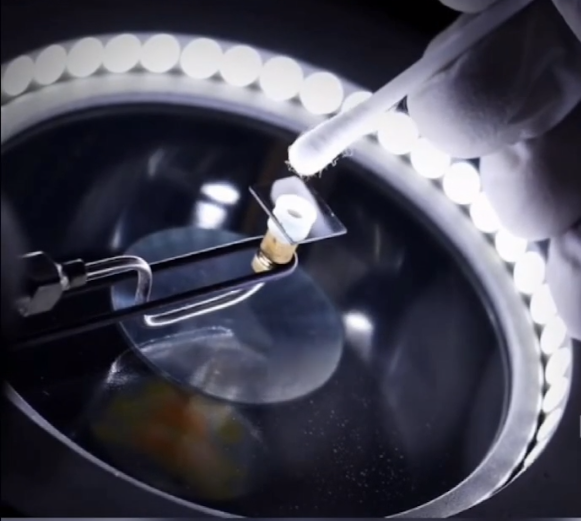

The process of cultivating diamonds comes from diamond seeds. In the laboratory, advanced equipment and cutting-edge technology are used to put gravel-sized or flake-shaped diamonds into the culture warehouse as seeds. These diamond seeds serve as an atomic structure template and provide a foundation for the growth of diamonds.

In the culture warehouse, a high-temperature and high-pressure environment is created. The temperature and pressure will rise rapidly, reaching a high-temperature and high-pressure environment more than 100 miles deep under the road, simulating the conditions for the formation of natural diamonds. This high-temperature and high-pressure environment is necessary to cultivate high-quality diamonds.

一、There are two methods: Chemical Vapour Deposition chemical vapor deposition, referred to as CVD, and High Pressure High Temperature, HPHT.

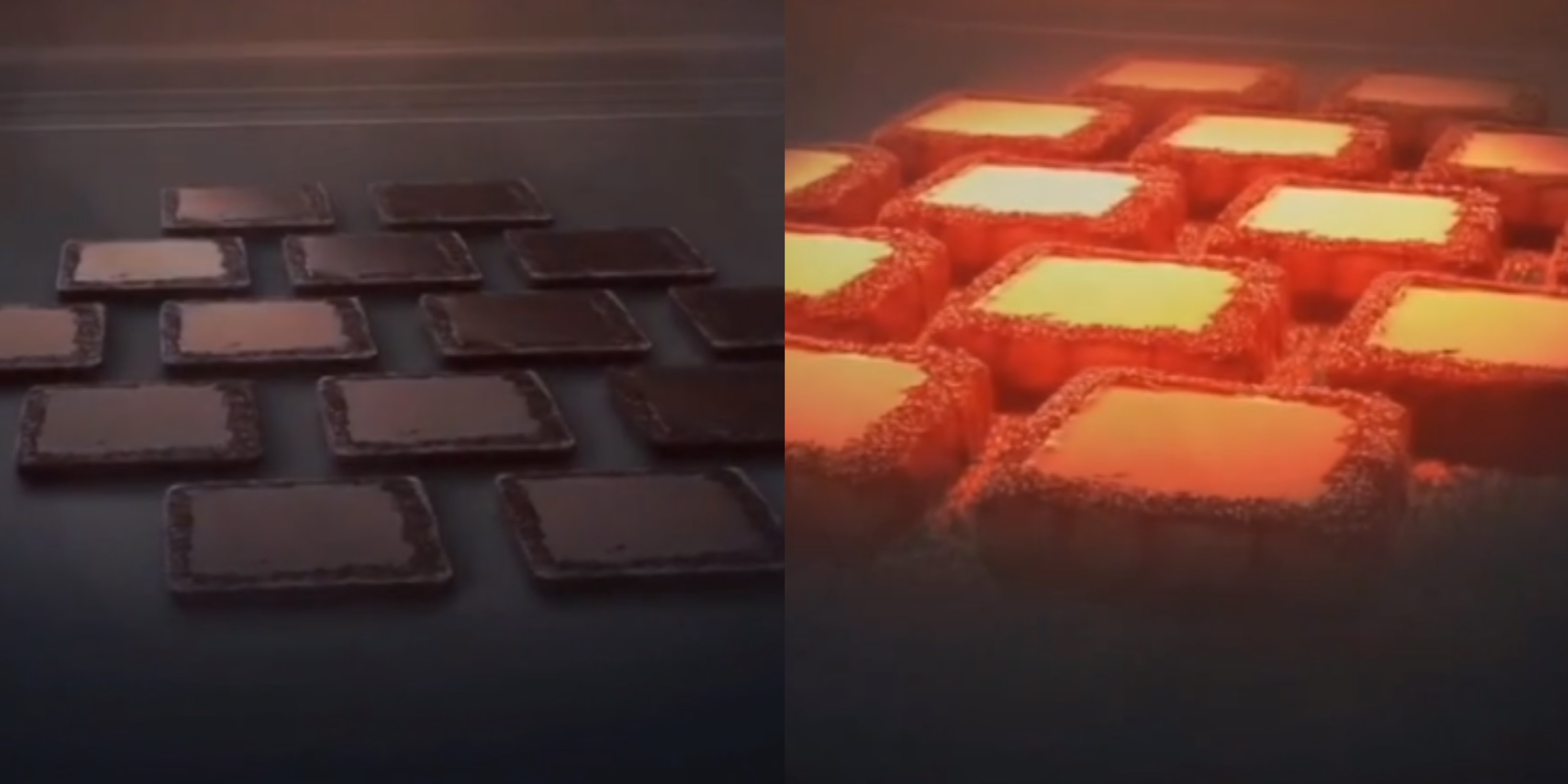

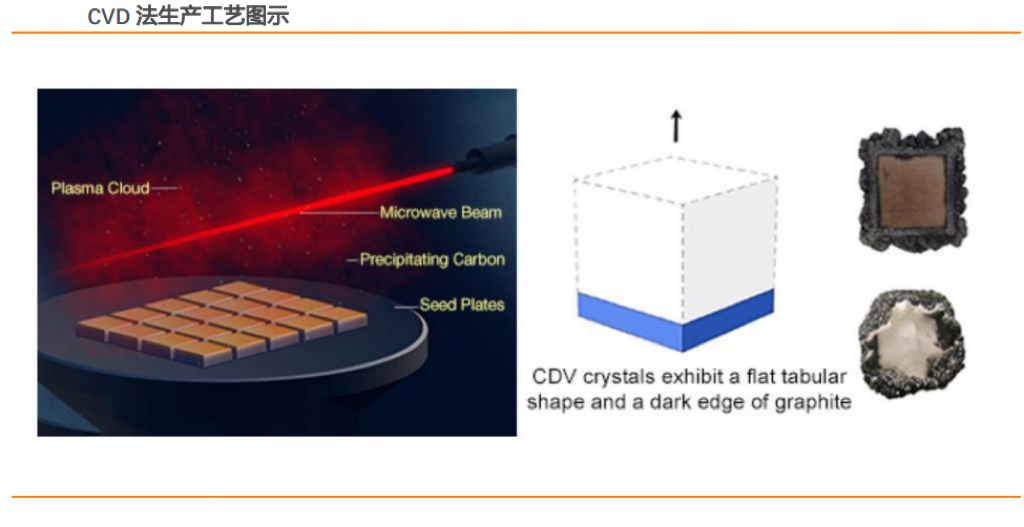

CVD chemical vapor deposition method: chemical vapour deposition uses one or more gases to chemically react on a heated solid substrate and coat it with a solid film. The so-called CVD diamond is a natural diamond as the mother stone. Assisted by high-purity methane, hydrogen, nitrogen and other gases, in the microwave oven, allows carbon molecules like diamonds in methane to accumulate on the diamond raw stone at high pressure. After layers of proliferation, transparent diamonds can be formed up to 10 carats. In order to make CVD diamonds grow smoothly, methane with diamond structure is commonly used in carbon sources. Methane can be regarded as a monoatomic diamond pressed with hydrogen. The quality of diamonds grown up like this is almost the same as that of natural diamonds, and it is difficult to distinguish them with the naked eye.

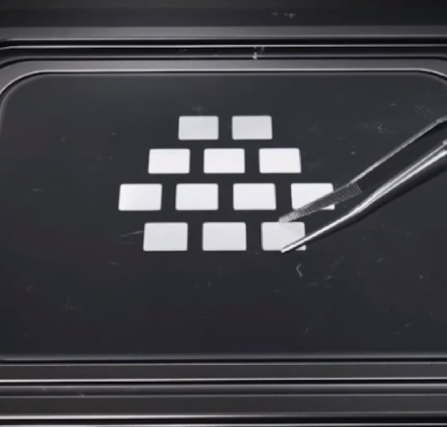

(1) Crystal selection: prepare and select high-quality diamond "seed" base 3 seed wafers.

(2) Arrangement: Arrange the selected seed wafer on the metal base in the device.

(3) Adjust equipment parameters: turn off the equipment and steadily control the temperature, pressure, gas flow, power and other start-up equipment of each growth parameter.

(4) Deposition growth: methane CH4 body and hydrogen H2 are injected and heated by microwave beam to form plasma, which is placed at 1500 degrees Celsius for 100 hours of growth.

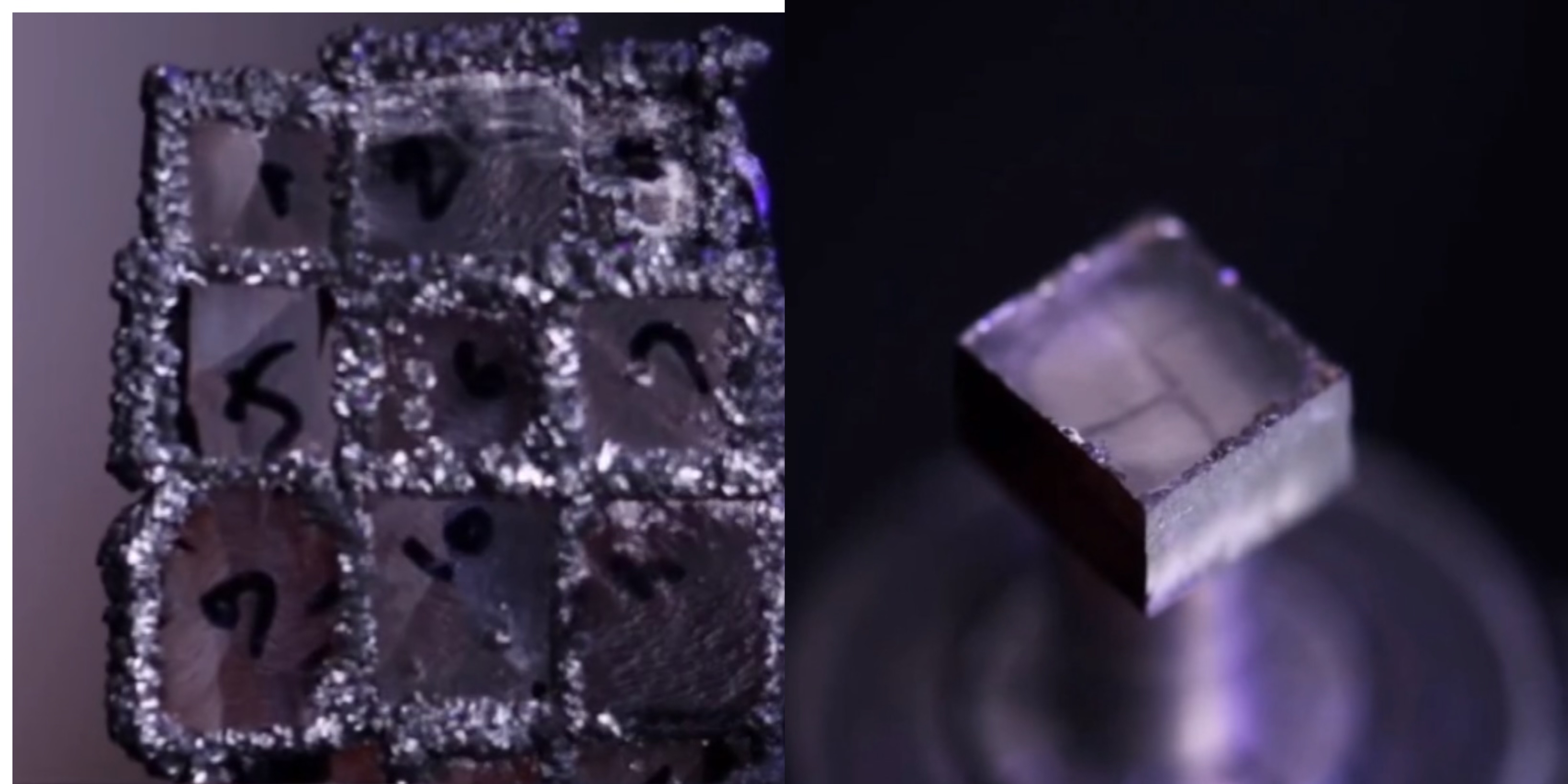

(5) Laser cutting: diamond raw stone is released. Due to the different growth rates of each surface in the growth process, it needs to be cut by precision laser after growth.

(6) Polishing: diamond raw stone cutting and polishing

(7) Bare diamond formation: So the diamond cultivated by CVD chemical vapor deposition method was born

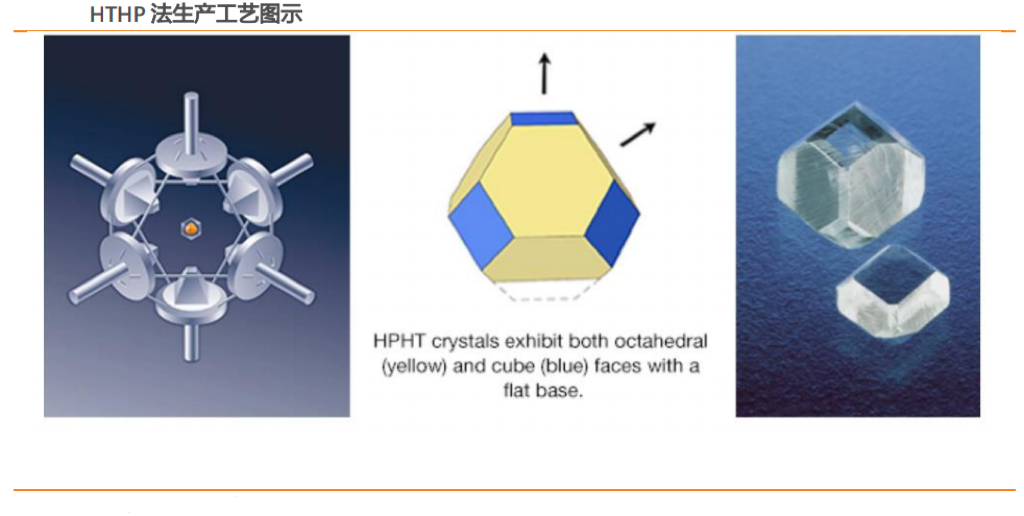

二、 HPHT high temperature and high pressure method will also be used:

HPHT represents high pressure and high temperature, which is one of the main methods for growing diamonds in the laboratory. This diamond growth process affects carbon by extreme temperature and pressure, aiming to replicate the extreme high temperature and pressure conditions formed by natural diamonds in the depths of the earth.

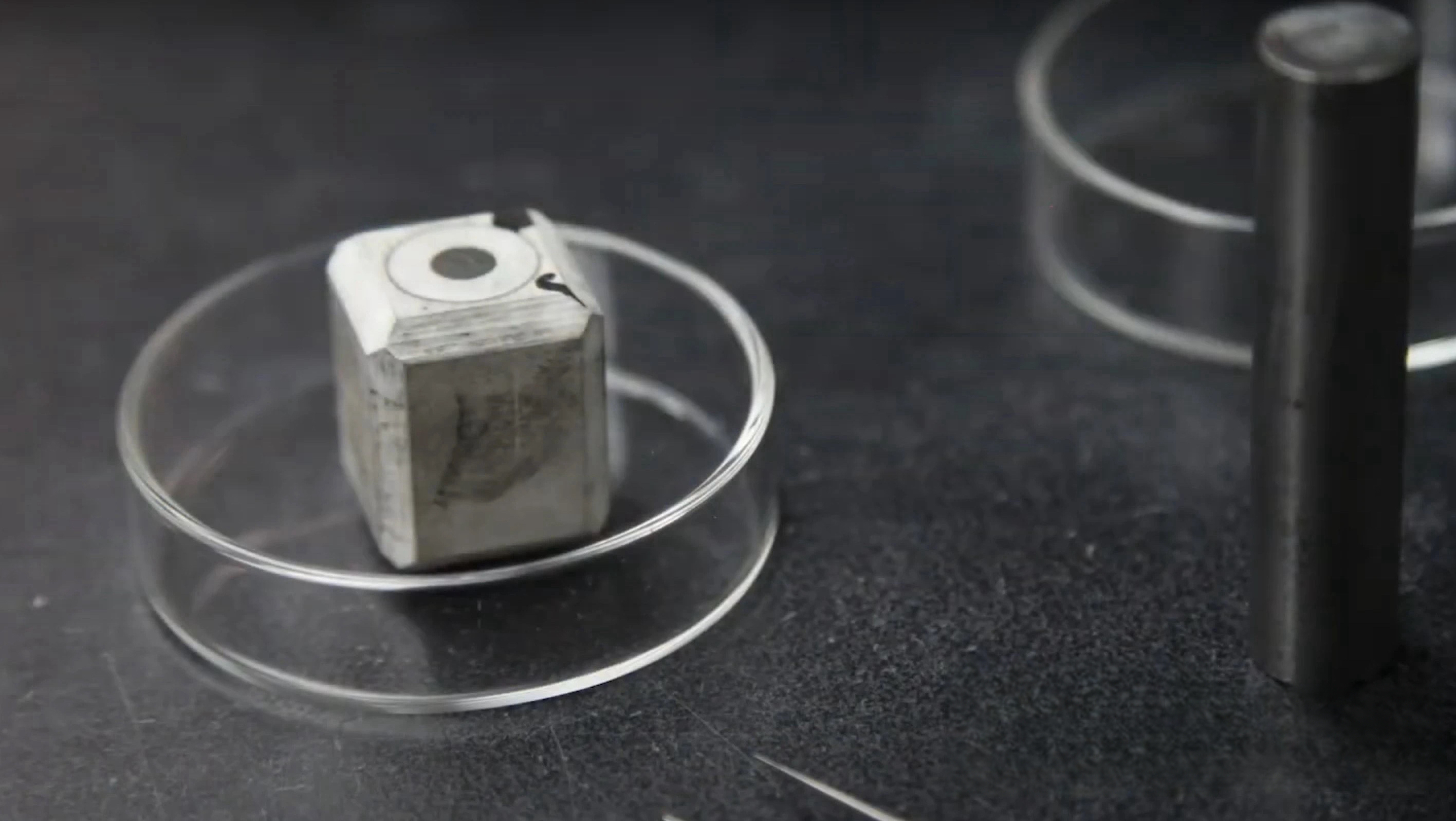

(1) High temperature and high pressure diamond growth process(2) Put diamond seeds into a specially designed press.

(3) The growth chamber is heated to 1300-1600°C, and the pressure is higher than 870,000 pounds per square inch.

(4) Melting metal dissolves high-purity carbon sources.

Carbon atoms precipitate on small diamond crystals, and artificial diamonds begin to grow. Then, the crystals cultivated in the laboratory are cut and polished by diamond cutting machines.

More specifically, high temperature and high pressure (HPHT) diamond growth occurs in small capsules in devices that can produce very high pressure. In the capsule, carbon raw materials (such as graphite) are dissolved in melting fluxes composed of metals such as iron (Fe), nickel (Ni) or cobalt (Co), thus reducing the temperature and pressure required for diamond growth. Then, the carbon material migrates to colder diamond crystals through flux and crystallizes on them to form artificial diamond crystals. Crystallisation occurs within a few days to weeks to grow one or more crystals.

Although natural diamond crystals often form octahet, HPHT synthetic diamond crystals usually have aspects in addition to octahet. Due to the different shapes of natural diamond crystals and high-temperature and high-pressure synthetic diamond crystals, their internal growth patterns are also very different. These growth patterns are one of the most reliable ways to distinguish natural diamond crystals from synthetic diamond crystals.

The resulting faceted synthetic gemstones usually show unique colour distribution, fluorescence partitions and texture patterns related to their cross-shaped growth fan structure, and sometimes contain dark flux metal inclusions. In some cases, even if the light source is turned off, the material will show phosphorescence and will emit light after exposure to ultraviolet rays. Planting colourless high-temperature and high-pressure synthetic materials used to be a challenge.

Nitrogen will make diamonds yellow, so they must stay away from the growing environment. In addition, growing high-purity colourless diamonds requires a longer growth time and better control of growth temperature and pressure conditions. However, recent technological advances have enabled the laboratory to produce colourless crystals of diamonds with facet of 10 carats and above.

In addition, carbon-containing nutrients are also needed to cultivate diamonds. Generally, graphite (C) or methane (CH4) will be selected as the carbon source and added to the culture tank. Under high temperature and high pressure environment and special treatment, the chemical bonds between carbon atoms in raw materials will break and become free carbon atoms. These free carbon atoms will be attracted by the nearby carbon atomic structure and gradually attach to the diamond seed.

Finally, by combining with the carbon atoms on the diamond seed, new chemical bonds are formed, thus allowing the seeds to grow gradually. The whole cultivation process takes a certain amount of time, depending on the size and quality of the diamonds required. It should be noted that although synthetic diamonds are very similar to natural diamonds in physical and chemical properties, their formation process is different. Natural diamonds have been formed after millions of years of crustal movement and a high-temperature and high-pressure environment, while synthetic diamonds are realised by artificial simulation of this environment.

Generally speaking, diamond cultivation is a process of gradually cultivating diamonds on the basis of diamond seeds using a high-temperature and high-pressure environment. High-quality diamonds can be synthesised by simulating the natural environment in the laboratory and adding appropriate carbon sources. The development of this technology makes it easier for people to obtain diamonds and meet the needs of the market.